Injection Molding

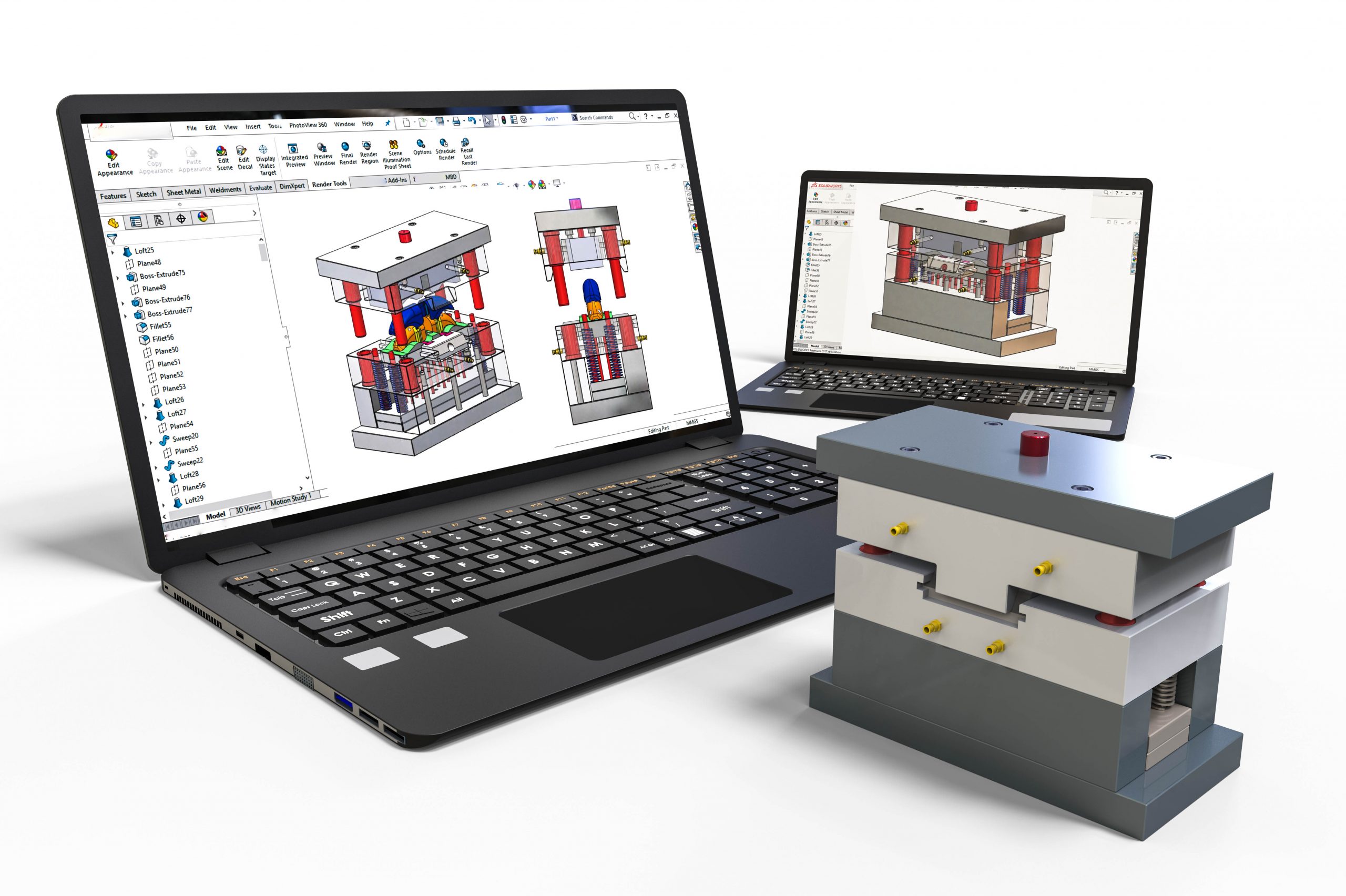

Specialists in injection molding services, mold design, and other tooling that will be used in each project. Our team works very closely to understand the application, evaluate tolerances, establish what quality metrics need to be in place, and deliver a solution.

What is Injection Molding?

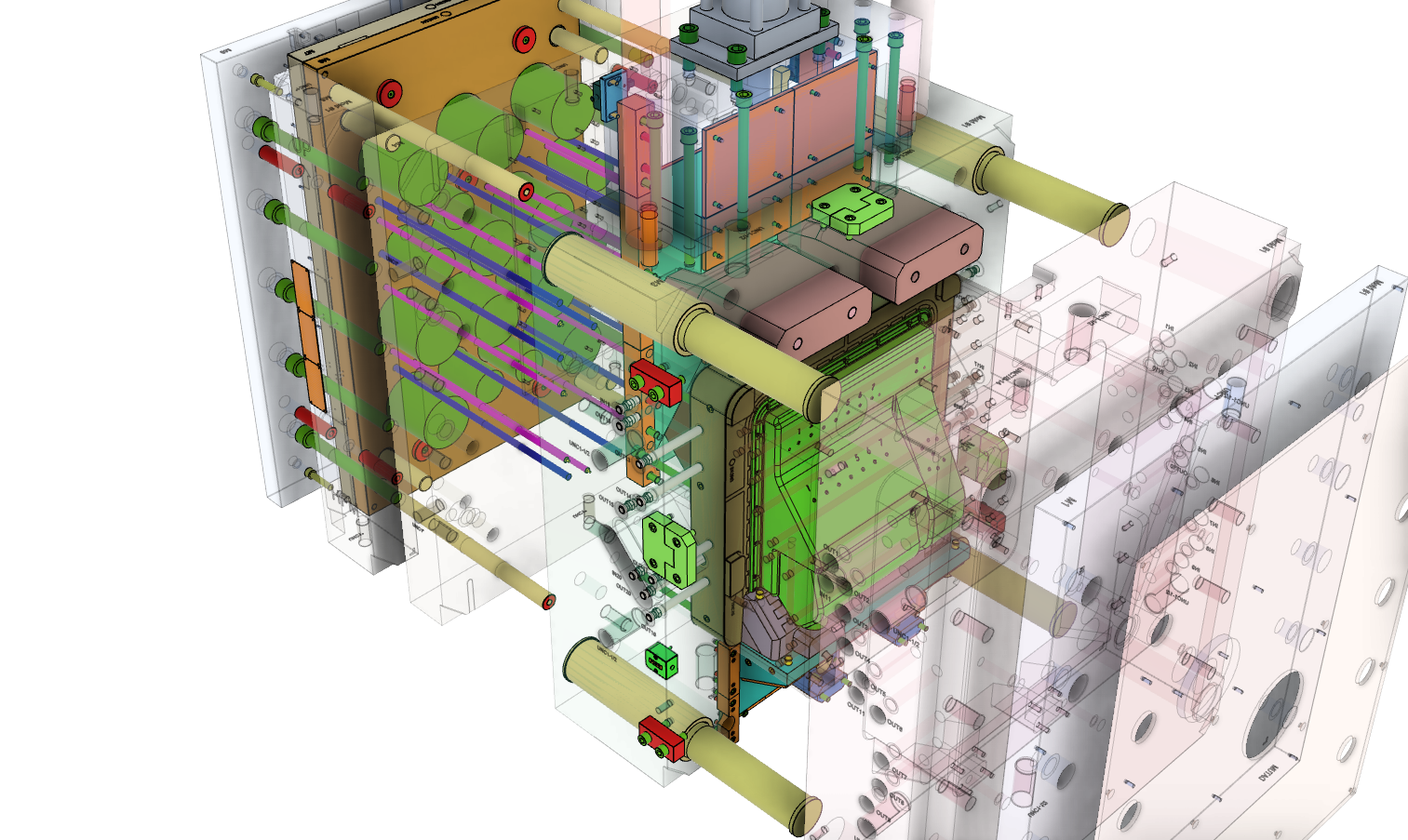

Injection molding is a complex manufacturing process. Using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a mold that’s fitted into the machine.

3D printing and injection molding are both techniques for producing plastic parts and components, but each manufacturing process has its own advantages and can be used together as complementary manufacturing methods.

Injection molding has longer turnaround times to prepare for the creation of parts (4-12 weeks even for simple parts), which means it is not well suited to frequent design changes. However, despite the long turnaround times this process is ideal for producing parts in mid to high volumes (500+ parts per run). The mold tool is also suited for producing large or small components of any complexity.

Injection Molding vs. 3D Printing

Injection molding is best suited for:

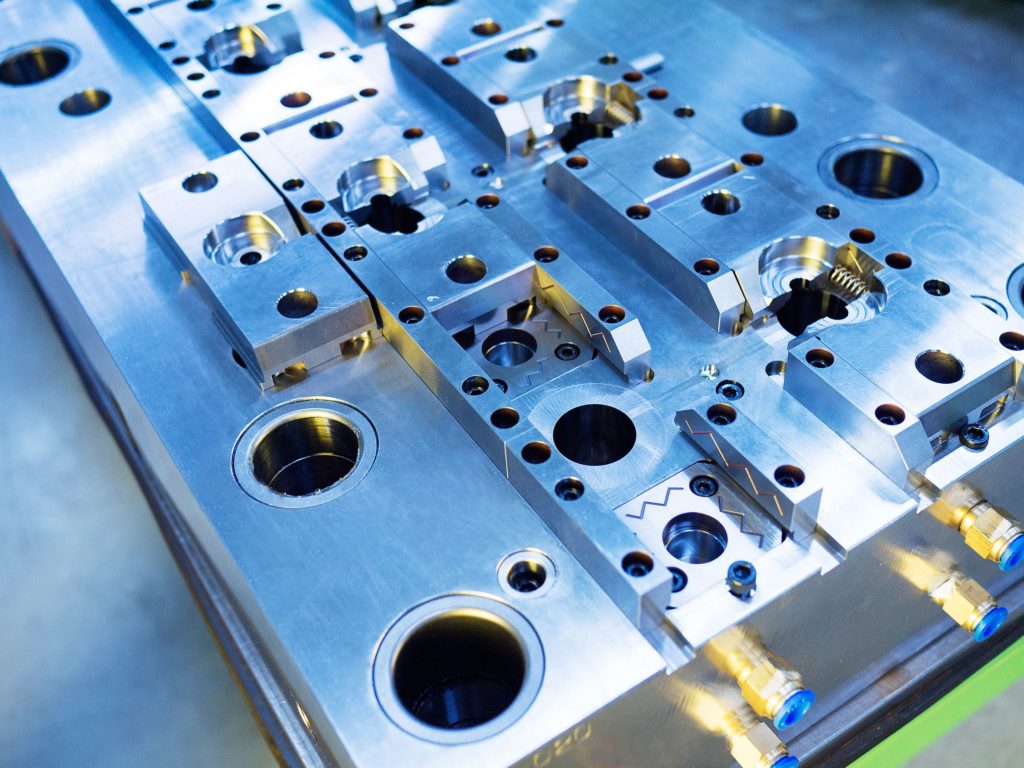

Large batch production as you can create multiple identical objects simultaneously

Strong, solid designs that are based on one continuous form

Smooth finishes for parts that move against other objects. The ease of creating smooth parts means that there is reduced friction as compared to the rougher finish associated with 3D printed parts.

Lower cost for medium to large production

3D Printing is best suited for:

Small batch production, including prototyping

Intricate designs with gaps or holes in the middle

Design changes, even during production

Lower cost for prototypes and small batches

Our team of specialists can guide you through the entire process.